Exploring AI-Driven Predictive Maintenance

Exploring AI-Driven Predictive Maintenance

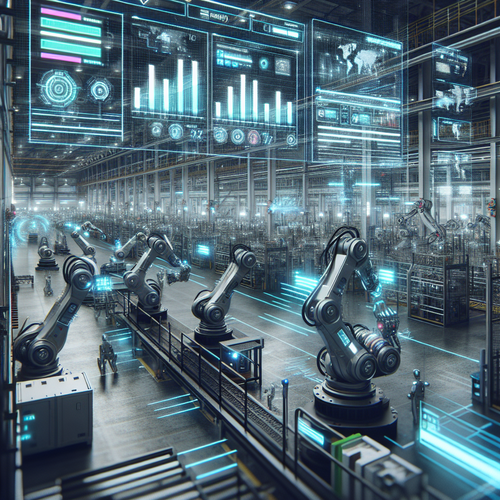

In today’s fast-paced industries, minimizing downtime and maximizing efficiency are critical priorities. Artificial Intelligence (AI) in predictive maintenance has emerged as a transformative approach to achieving these goals. By leveraging data analytics and machine learning algorithms, predictive maintenance allows businesses to anticipate equipment failures before they occur, scheduling necessary maintenance activities at optimal times.

Understanding the Basics of Predictive Maintenance

Predictive maintenance utilizes targeted data analysis to predict machinery breakdowns. It involves continuous monitoring of equipment conditions through the use of IoT devices and sensors. This real-time data collection enables the identification of patterns and anomalies that signal potential issues.

Key Benefits

The integration of AI into predictive maintenance offers several significant advantages:

- Reduced Downtime: AI allows for early detection of faults, leading to minimized operational interruptions.

- Cost Efficiency: Proactive maintenance helps avoid costly emergency repairs and extends equipment lifespan.

- Enhanced Safety: Regularly maintaining equipment reduces the risk of accidents due to wear and tear.

Implementation Process

Implementing AI-driven predictive maintenance involves several steps:

1. Data Collection

Gather data from various sensors installed on equipment. This data, typically stored in the cloud, includes temperature, vibration, pressure, and other relevant metrics.

2. Data Processing and Analysis

The collected data is processed using advanced algorithms. Machine learning models, trained on historical data, detect patterns that indicate potential issues. Managing Kubernetes with Rancher offers similar insights into system efficiency, ensuring optimal performance and management.

3. Actionable Insights and Maintenance

Based on the analysis, actionable insights are generated to prompt the maintenance team to perform necessary interventions. Efficient predictive maintenance drives better resource allocation and workforce utilization.

Challenges and Solutions

Implementing AI-driven predictive maintenance poses challenges such as initial high costs and complex integration with existing systems. However, these can be mitigated by selecting scalable solutions and leveraging cloud-based analytics platforms.

The Future of Predictive Maintenance

As technology advances, AI-driven predictive maintenance will become more sophisticated, incorporating deeper learning algorithms and enhanced sensor capabilities. This evolution will further revolutionize industries by optimizing asset performance and reducing overall costs.

Integrating AI into maintenance strategies not only enhances operational efficiency but also positions businesses to compete more effectively in the Industry 4.0 landscape.

Conclusion

Embracing AI-driven predictive maintenance transforms maintenance strategies, making them more proactive and data-driven. As businesses continue to prioritize uptime and efficiency, AI’s role in industrial maintenance will only expand.

For more insights on integrating AI within various sectors, explore our given articles about smart logistics solutions.