The Rise of AI in Predictive Maintenance

The Rise of AI in Predictive Maintenance

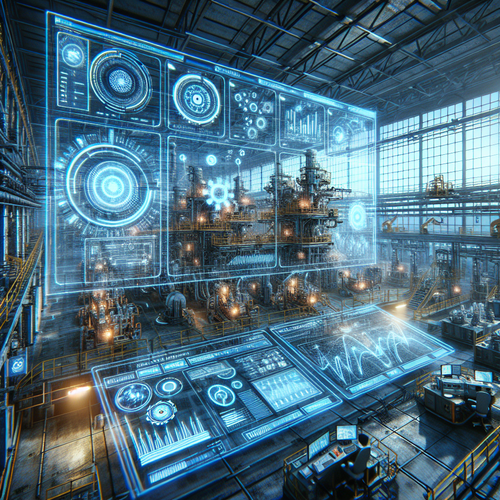

In an era where technology continuously evolves, industries are increasingly turning to AI for predictive maintenance. This innovative approach utilizes advanced analytics to anticipate maintenance needs, allowing companies to prevent equipment failures before they occur.

Understanding Predictive Maintenance

Predictive maintenance involves using data and analytics to determine the condition of equipment, enabling maintenance to be scheduled just in time. This proactive strategy contrasts with traditional reactive maintenance, which only addresses issues after they arise.

Benefits of Predictive Maintenance

- Reduced Downtime: By identifying potential failures before they happen, organizations can schedule maintenance during non-peak hours, minimizing disruption to operations.

- Cost Savings: Preventing unexpected breakdowns usually incurs lower costs compared to emergency repairs.

- Extended Equipment Lifespan: Regular monitoring and timely interventions can extend the life of machinery, enhancing return on investment.

The Role of AI in Predictive Maintenance

AI is revolutionizing predictive maintenance through various capabilities:

- Data Analysis: AI can analyze vast amounts of data from sensors and other sources far more efficiently than human operators. This includes historical data as well as real-time information.

- Machine Learning: By utilizing machine learning algorithms, AI systems learn from historical failures and maintenance records, continually improving the accuracy of predictions.

- Anomaly Detection: AI can detect unusual patterns or anomalies in machine behavior, signaling potential issues that require attention.

Real-World Applications of AI in Predictive Maintenance

Several industries are leveraging AI technology for predictive maintenance:

- Manufacturing: AI-driven solutions monitor the performance of machines and equipment, allowing for timely maintenance that avoids costly production delays.

- Aerospace: Airlines use predictive maintenance to ensure aircraft reliability, keeping them operational and compliant with safety regulations.

- Oil and Gas: Companies in this sector utilize AI to monitor drilling equipment and pipelines, reducing downtime and enhancing safety.

The Integration of IoT with AI for Enhanced Predictive Maintenance

The integration of Internet of Things (IoT) technology with AI is a game changer for predictive maintenance. IoT sensors can collect data from machinery, which can then be analyzed by AI systems.

- Real-Time Monitoring: IoT devices continuously monitor equipment health, feeding real-time data to AI algorithms for immediate analysis.

- Predictive Analytics: Combining IoT data with AI allows for deeper insights and more accurate forecasting, leading to even better maintenance strategies.

Challenges and Considerations

While AI presents many benefits for predictive maintenance, some challenges need to be addressed:

- Data Security: The vast amount of data generated requires robust security measures to protect sensitive information.

- Implementation Costs: Initial investments in AI technology and training of staff can be significant.

- Skill Gaps: Organizations must ensure they have the right talent in place to manage and interpret AI-driven insights effectively.

Conclusion

The rise of AI in predictive maintenance heralds a new era of efficiency and reliability for industries reliant on machinery and equipment. By harnessing the power of advanced analytics, businesses can reduce downtime, save costs, and enhance operational effectiveness. For further insights into how AI is reshaping technology, check out our post on The Rise of AI-Driven Cybersecurity Solutions. Embracing these advancements will pave the road for a more resilient and productive future in maintenance management.